YouTube - MaxHP Fiesta ST Build Feature, B-Roll Music Edit. Footage provided by Nick VanRyswyk (@MaxHP), Video/Music Editing by Ashton X Moore.

↓ Vacuum Insulated Intercooler Sprayer System ↓

With a significant increase in power comes an increase in heat produced. Intercoolers play a very important role in reducing heat soak, allowing turbocharged engines to run cooler and safely generate more power.

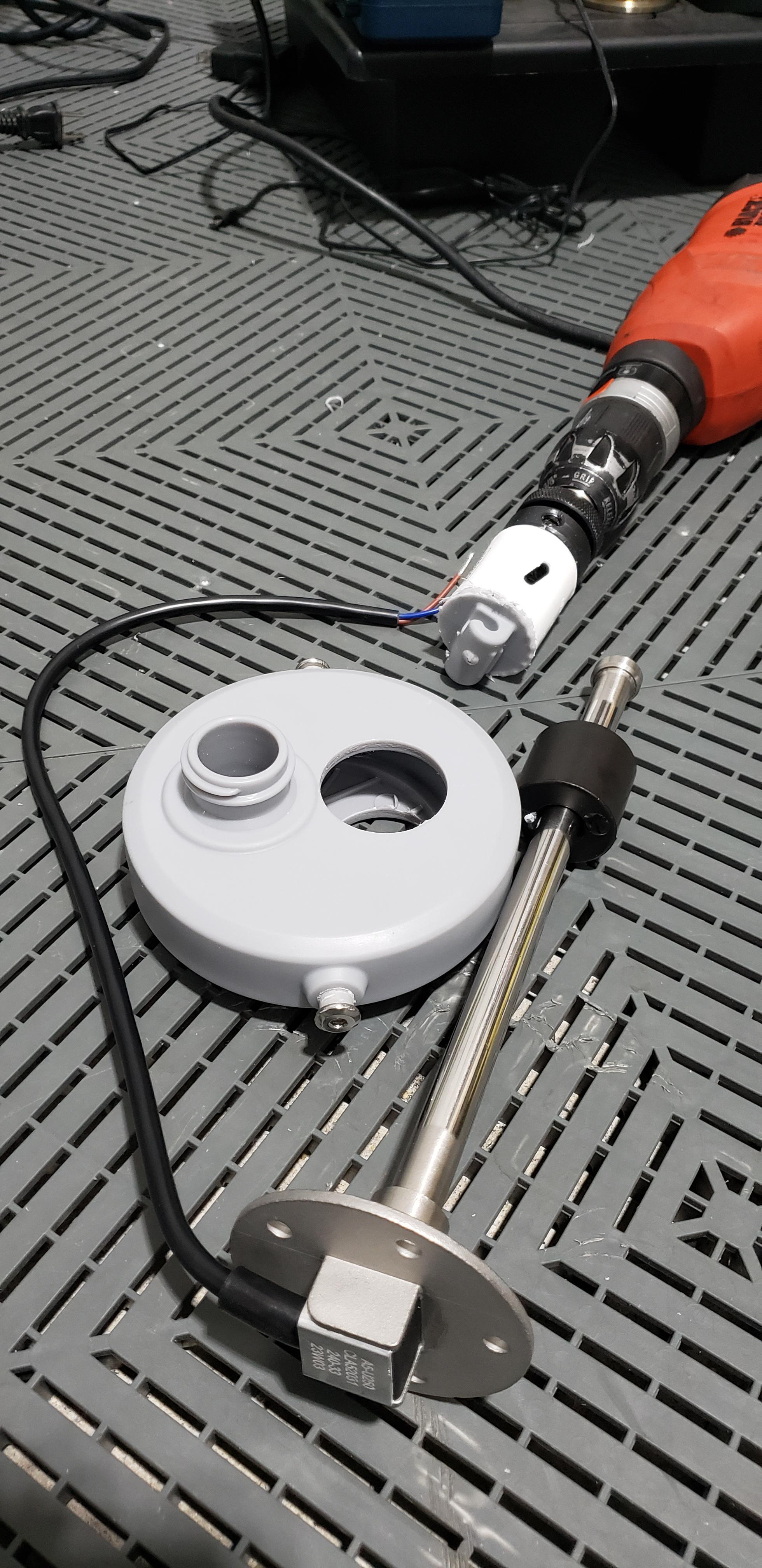

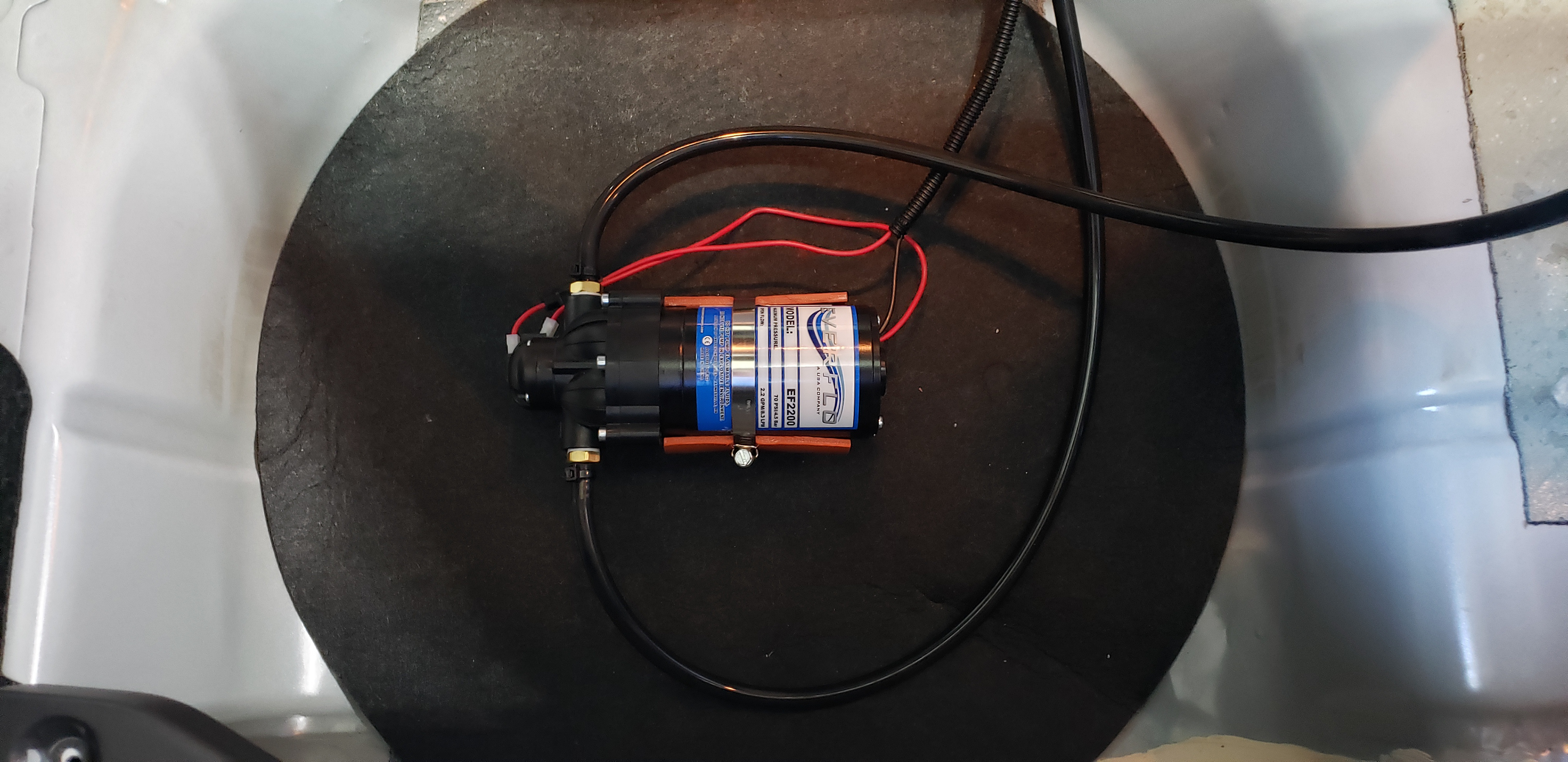

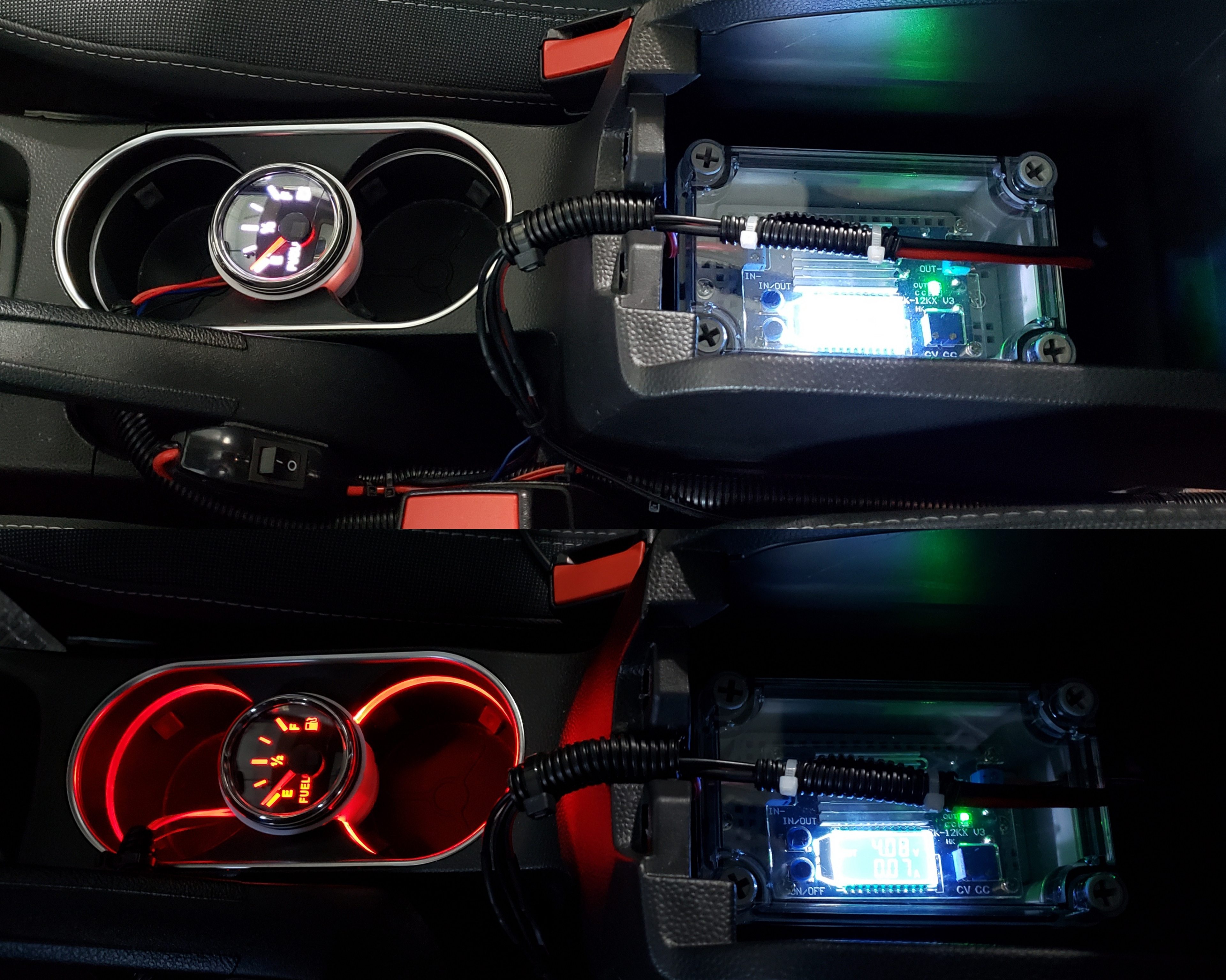

To fight this, I designed and prototyped my own adjustable intercooler sprayer system entirely from scratch to greatly boost the efficiency of my front-mount intercooler. The insulation allows the spray liquid to stay cold for prolonged periods of time and boosts how effectively it can cool charge temperatures. In the center console, I wired an adjustable voltage regulator so I can adjust flow rate and pressure to control how much and how quickly the fluid is pumped from the tank.

Additionally, I installed a liquid level sensor and gauge so I can monitor how much fluid is left in the tank to avoid running the pump dry.

↓ Intercooler Sprayer Nozzle Refinement ↓

Here, I tested several sprayer nozzle configurations with different materials and mounting methods. Chronologically from left to right, I focused on reducing the profile of the sprayers as much as possible while searching for higher quality materials.

Eventually, I ended up with a much cleaner and more polished final variation. I also greatly improved the efficiency, allowing the sprayer to operate much longer between refills.

↓ Upgrading Bottom-End, Installing King Racing Bearings ↓

Unfortunately, one of the dangers that comes with pushing high amounts of power is significant internal stress. I eventually discovered these limits, was forced to learn how to remove and upgrade all the crank bearings of my own motor after signs of failure began to emerge. A first-time task, this was a major learning experience for me as I entered into the fundamentals of engine work.